Sensor-based electronics play a crucial role in modern robotics, automation, and intelligent control systems. However, off-the-shelf solutions often suffer from reliability issues such as environmental interference, power disconnections, or limited adaptability. To address these challenges, we developed the USM16-6CH Ultrasonic Module—a fully integrated six-channel board designed for stable performance, simplified installation, and versatile communication options.

BACKGROUND

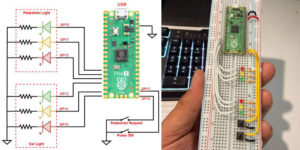

Our earlier project—a collision-assist remote-controlled car—relied on infrared sensors. While functional, it failed under daylight conditions due to infrared light sensitivity. After experimenting with workarounds, we concluded that a shift to ultrasonic sensing would provide a more reliable solution.

Instead of spreading components across multiple boards, we designed a single, compact module that integrates six transducers and a control unit. This not only improved stability but also minimized the risk of power disconnections during operation.

PLANNING AND DESIGN

The heart of the module is the RCWL-9610, a microcomputer chip that processes ultrasonic signals between the sensors and microcontroller. Unlike popular low-cost modules such as the HC-SR04, our design emphasizes robustness and flexibility.

- SMD-based Design: Transitioning from through-hole to surface-mount components reduced board size and enhanced reliability.

- Four Communication Protocols: GPIO, UART, I²C, and 1-Wire are supported, selectable via a 2-way DIP switch.

- Simplified Wiring: Sensors connect with flexible wires instead of fragile power leads, reducing signal loss risks.

Figure 1 – Electrical Schematic of a Single Channel

TECHNICAL SPECIFICATIONS

Table 1. Input/Output Configuration and Performance Parameters

| Parameter | Remark | Min. | Typ. | Max. | Unit |

| Operating Voltage | 2.8 | – | 5.5 | V | |

| Operating Current | – | 2 | 3 | mA | |

| Detection Distance | Flat wall | 350 | 400 | 600 | cm |

| Working Frequency | – | 40 | – | kHz | |

| Blind Spot | Random value in zone | – | 2 | 3 | cm |

| Detection Accuracy | Same temperature | – | ±2 | – | % |

| Resolution | Theory | – | 1 | – | mm |

| Detection Angle | Max. direction angle | – | ±15 | ±20 | ° |

| Measuring Cycle (GPIO/1-WIRE) | – | 70 | – | ms | |

| Measuring Cycle (UART/I²C) | – | 120 | – | ms | |

| Output Interface Mode | GPIO / UART / I²C / 1-WIRE | – | – | – | – |

| Storage Temperature | -50 | – | 100 | °C | |

| Operating Temperature | -40 | – | 90 | °C | |

| Package Size | SOP16 | – | – | – | – |

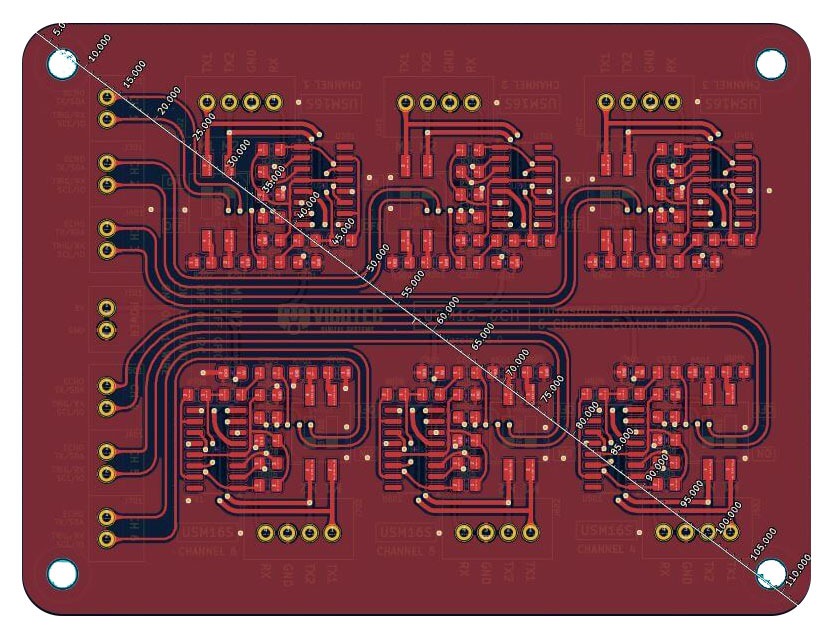

PCB DESIGN

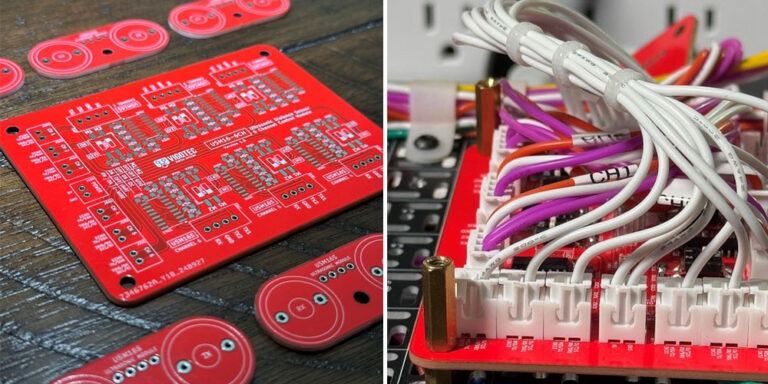

The USM16-6CH was designed using KiCad, with all schematics finalized before exporting fabrication files for manufacturing. Unlike previous boards built entirely with through-hole components, this project introduced Surface Mount Devices (SMDs).

This transition brought challenges but also enabled a more compact, professional layout. Only the connectors remained through-hole, while all other components were SMD-based for performance and stability.

Figure 2 – PCB Design of the USM16-6CH

Figure 3 – 3D PCB view

COMPARISON WITH EXISTING SOLUTIONS

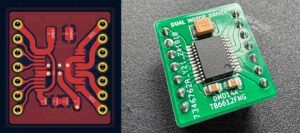

Low-cost ultrasonic sensors like the HC-SR04 can be effective in simple projects but are often unreliable in real-world conditions. Power disconnections and environmental interference are common issues.

The USM16-6CH addresses these shortcomings by integrating all sensors and processing into a single stable board. Flexible wiring replaces fragile power connections, reducing failures caused by motion or stress.

Figure 4 – HC-SR04 vs. USM16-6CH

Unlike most ultrasonic sensors that lock users into a single protocol, the USM16-6CH supports four: GPIO, UART, I²C, and 1-Wire. A simple DIP switch configuration makes mode selection straightforward—removing the need for solder jumpers.

Figure 5 – Input/Output DIP Switch Configuration

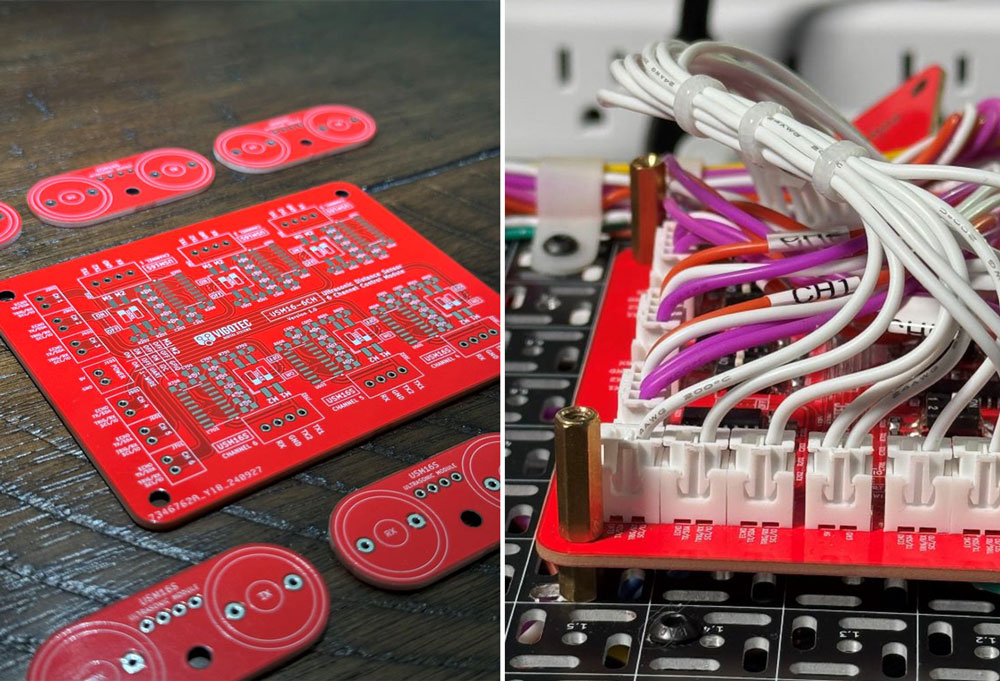

Figure 6, below, shows a picture of the actual board not assembled and the same board already being used in its first prototype, the Collision Assist Remote Control Car with 6-CH Ultrasonic Module.

Figure 6 – Fabricated board not yet assembled (on the left) and the assembled board (on the right).

APPLICATIONS AND FUTURE USE

While originally built for a remote-controlled car project, the USM16-6CH can be applied to drones, robots, and other automation systems where reliability is paramount. Its modularity and communication versatility allow easy integration into a wide range of devices.

By addressing sensitivity and stability challenges common in commercial modules, this design demonstrates how custom-built solutions can outperform generic alternatives in critical applications.

CONCLUSION

Building the USM16-6CH was more than just a technical project—it was about solving real problems we faced with earlier designs. By rethinking how ultrasonic sensing should be implemented, we created a compact and reliable module that’s easy to integrate and adapt. What started as a fix for a remote-control car grew into something much bigger: a tool that can power future ideas in robotics, drones, and automation with more stability and confidence.